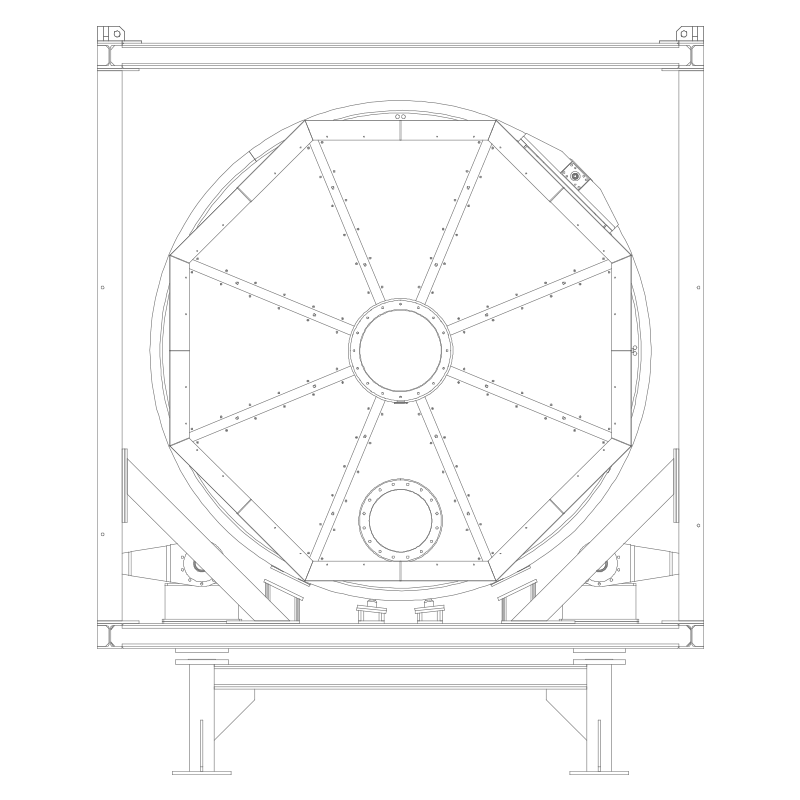

The BioDryer technology was originally designed specifically for Biosolids. Experience virtually no down-time, produce Class A Biosolids and reduce the total weight by ~70%!

BioDrying

The most efficient way to remove water from biosolids and organic waste.BioDrying is the process by which biodegradable material is rapidly heated through initial stages of composting to reduce moisture and consequently reduce its overall weight. This modular drying system is designed to remove moisture from Biosolids while using 50% less energy compared to gas heated systems like belt dryers.