Sustainable Biosolids Management is a step forward the circular economy. Pyrolysis brings to municipalities the ultimate solution for biosolids.

WHAT IS PYROLYSIS

Pyrolysis can be defined as the thermal decomposition of organic material through the application of heat without the addition of extra air or oxygen. Through this process, that takes place at temperatures between 660 and 1,650 degrees F, two co-products are obtained: syngas and Biochar. The Pyrolysis machines utilize this principle to produce renewable energy from any organic waste.

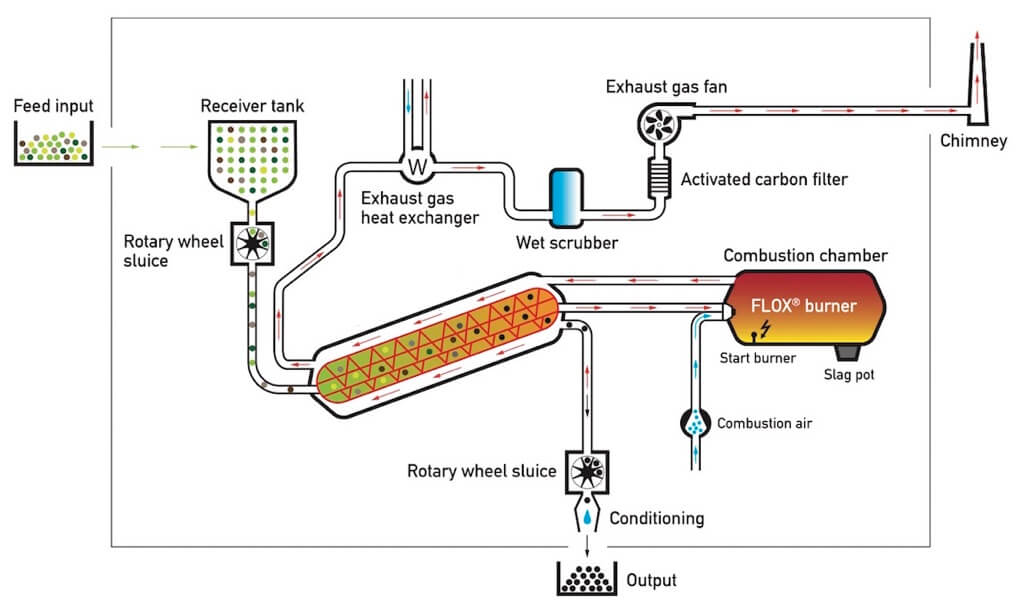

Self-Sustained Process

The most sustainable technology for organics upycling.This pyrolysis system utilizes the heat self generated by the syngas oxidation to sustain its own process without the need of external heat sources (like fossil fuels). The process generates heat in the form of hot water that can be used for drying or other needs.

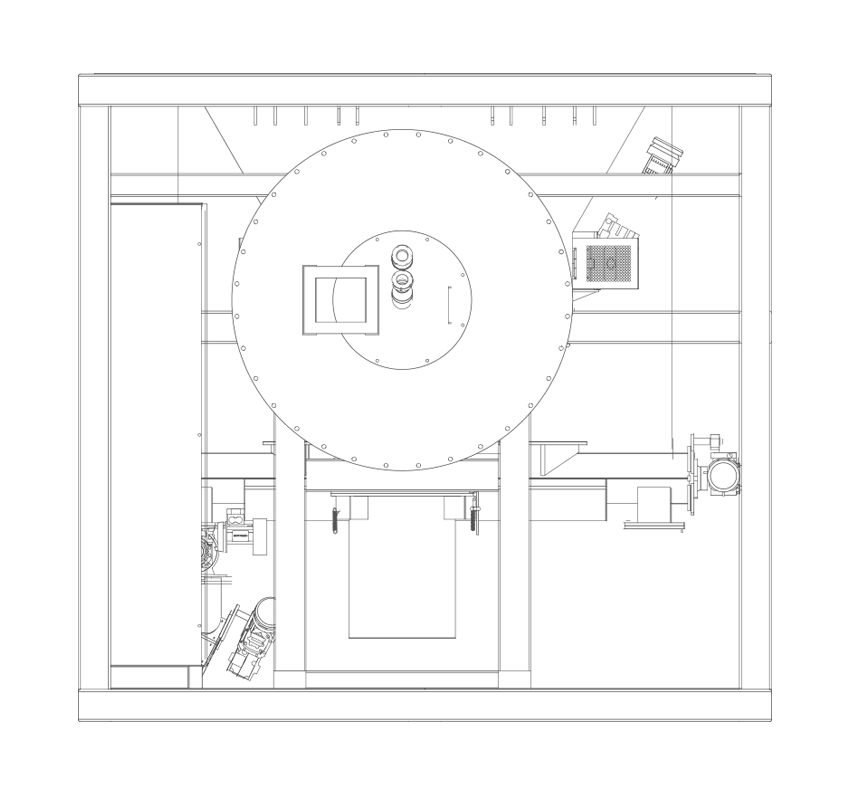

Skid mounted Machines

lb/h

lb/h

lb/h

Technology key points

Materials

The pyrolysis units are made of top grade stainless steel for best performance in all environments.

Performance

More than twenty units currently operating allowed us to optimise the process and generate up to 1.35 MMBTU/H per unit of usable heat.

Automation

The Pyrolysis is controlled by the latest Automation technology. Automated reports, predictive maintenance and self-adaptive algorithms brings you the Industry 4.0+ from day 1.

Durability

High temperatures and corrosive environments can lower the lifespan of a machine. The Pyrolysis is designed with durability in mind, this is why only the best materials and brands are used to manufacture the system.

Self-Sustained

A self sustained process guarantees 24-7 operations while generating renewable energy.

HIGH-QUALITY Biochar

Constant temperatures and residence time guarantee the highest quality of Biochar.

TECHNICAL OVERVIEW

| Gas Burner Capacity | From 290kW |

| Gas Burner Temperature | 900 / 1100 ºC |

| Pyrolysis Reactor Temperature | 450 / 750 ºC |

| Dimensions | 3m wide x 9m long x 5.6m tall |

| Loading Hopper Capacity | 2 Cubic Meters |