THE BIOFORCETECH PROCESS

From organic waste to value, The Bioforcetech system generates renewable energy, and UpCycles any organic waste into Biochar.

From organic waste to value, The Bioforcetech system generates renewable energy, and UpCycles any organic waste into Biochar.

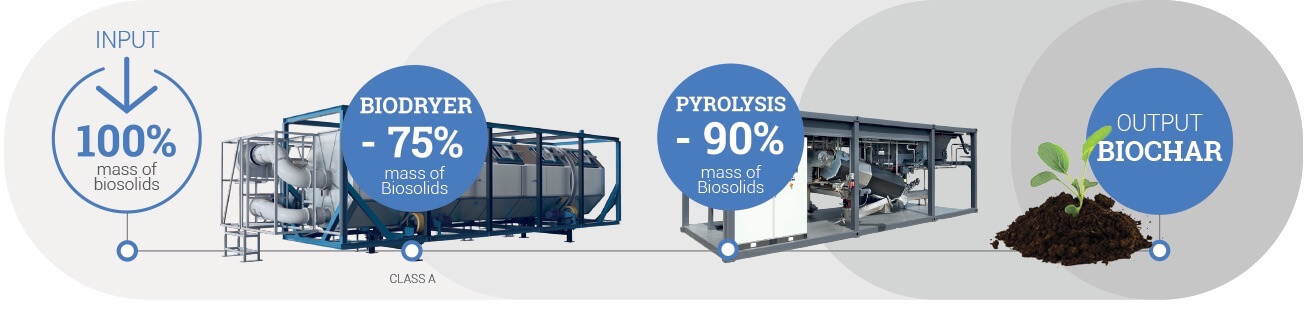

The Bioforcetech process is divided into 2 steps: BioDrying and Pyrolysis. Both systems can be installed independently or combined. When treating sewage sludge (Municipal Biosolids or industrial sludge) the combination of the 2 processes ensure net-energy processing without additives or bulking agents. Watch the video to see the transformation!

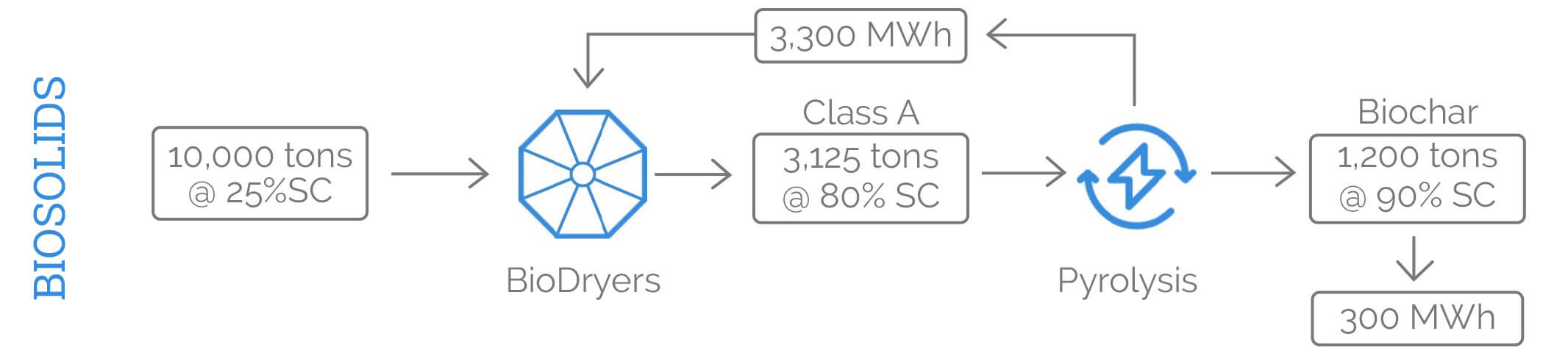

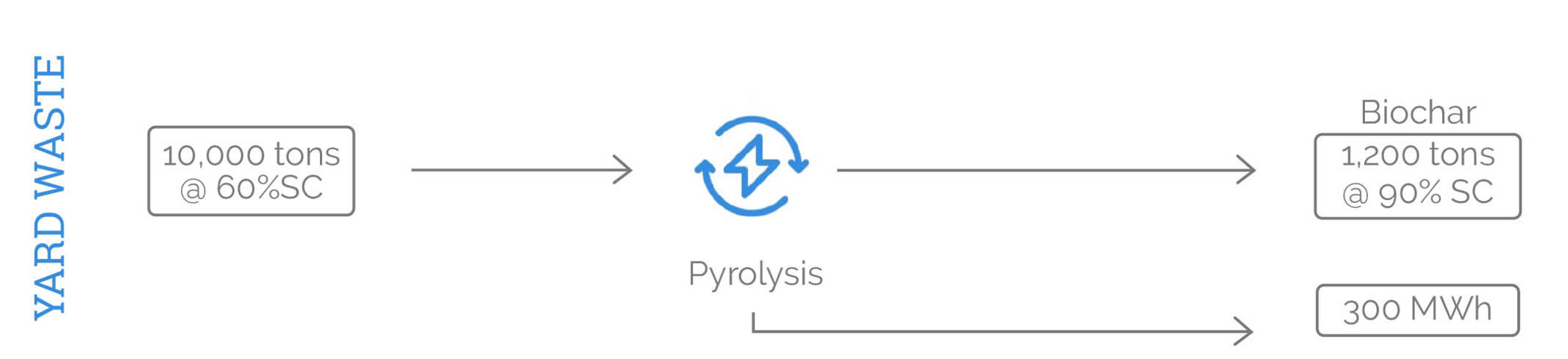

The schematics below shows the mass and energy balance of a Bioforcetech system. The first one Upcycles 10,000 tons per year of Biosolids into Biochar, the second one Upcycles 10,000 tons of yard waste into Biochar. (%SC stands for "% of Solid Content")

This calculator presents only an estimate. For an accurate evaluation of the project, please contact us